Making sense of Feeds and Speeds

- Phil Barrett

- Aug 26, 2022

- 5 min read

Updated: Aug 19, 2023

When I started out, one of the more confusing aspects of CNC machines was the concept of Feeds and Speeds. It seemed like a lot of math with no real explanation of how it all worked. A lot of people bandied "Feeds and Speeds" about without ever explaining them. And, coming from a wood working background using routers , it seemed like F&S was an unnecessary thing to study. Wood is awfully forgiving. But, it turns out plastic and metal aren't. The good news is it is a fairly simple concept and many CAD/CAM programs make it really easy.

What is Chip Load and why is it important? The first thing to understand is that Feeds (the feed rate the bit is moved through the material) and Speeds (the rate of the spindle spins at) are really not the key point. It is something called chip load - basically, the thickness of the chip that is cut off in a single revolution of one cutter of the bit. A bit, when it cuts through a workpiece, generates heat which needs to be removed. By cutting the properly sized chip, the heat will be carried off and the bit will run cool. If too small a chip taken off, a lot of heat will remain in the material and cause the bit to heat up. A bit that runs hot will dull sooner, give a poor quality cut and possibly damage the material. Most bit manufacturers will recommend a chip load for each bit and a given type of material.

Getting the right Chip Load

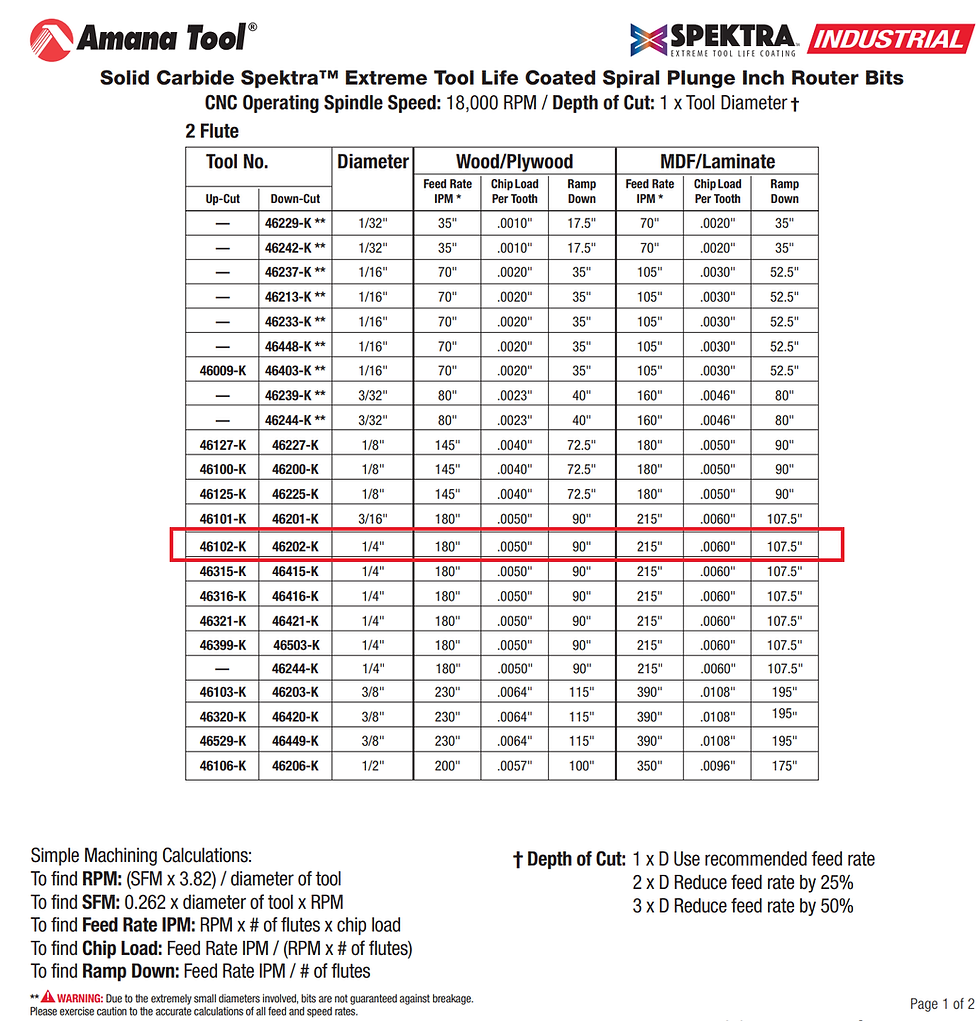

Lets look at a typical router bit and see how this works. I've chosen a fairly common type of bit, a 1/4" 2 flute up-cut spiral from Amana - #46102-K. As you can see in the chart below, Amana recommends that when cutting Wood/Plywood, you use 180 IPM feed rate and an 18,000 RPM spindle speed. This gives it a 0.005" chip load.

Adapting it to your needs

But what if your machine can not handle that cutting speed? 100 IPM is a common top end speed for a lot of hobby CNC machines. If we slow down the feed rate to 100 IPM then we need to lower the spindle speed to keep the chip load at 0.005". At the bottom of the above chart, there are some formulas that would allow you to figure out the new spindle speed. This is where many CNCer's eyes roll back into their heads! But, there is some good news, often CAD/CAM software will do it for you.

I use Vectric VCarve Pro and it has a very nice section for defining tools (bits) and specifying Feeds and Speeds. You can see that when I plug in 100 IPM and 10000 RPM, we get the desired chip load of 0.005". Note that often the Vectric software does not set the number of flutes (No. Flutes) in the Edit Tool panel so you may need to set that.

If your CAD/CAM software does not do this, you can still calculate the right spindle speed by using the ratio of new feed rate divided by recommended feed rate. In this case 100/180 or 0.556 (actually, 0.5555555...). Then multiply that times the recommended spindle speed to get the new spindle speed - 18000 * 0.556 or 10008. I used 10000 in the above example, close enough.

As you can see in the above calculations, the new IPM or RPM can be determined with a divide and a multiply.

Plastic and Metal

As was said earlier, wood is forgiving. However plastic and metal are not. Plastics like acrylic or polycarbonate will melt and make a mess if too small a chip load. With too large a chip load, they will chip or crack. With aluminum the incorrect chip load can result in heating or chatter and give a very poor finish or even a break the bit. Most manufacturers have recommended chip load for plastic cutting bits. Using an Amana 1/4" Spiral "O" flute router bit, 51404-K, we see that they recommend a range: 145-220 IPM, 18000 RPM and 0.008"-0.012" Chip Load. We can pick 0.01" as the target chip load. Using the VCarve tool form with the Amana supplied information and setting Feed Rate to 100 IPM, we find that 10000 RPM provides a 0.01" chip load. Using the ratio method and 200 IPM as the recommended feed rate we wind up with 9000 RPM. Note that choosing 200 IPM results in a chip load of 0.0111 which is still within the recommended range. For the IPM calculations, I assume 10000 RPM. which is for a 0.01" chip load.

It is interesting to note that plastic chip loads tend to be bigger because more heat needs to be removed to avoid damage to the material.

What if I can't find a chip load for my bit?

There are lots of "no name" bits available on Amazon, eBay, AliExpress and similar., usually at a bargain price. And they almost never have recommended Feeds and Speeds let alone chip load. So what do we do? I won't dwell on the wisdom of buying cheap bits but if you do, you can still get a reasonable chip load for them. It turns out that similar bits usually have very similar F&S plus chip loads. So if you have a random bit you acquired from Amazon, find a similar one from a manufacturer that does have F&S and chip load data and use that. There is no guaranty that will be correct but better than flying blind. You should, however, run a test cut and look at the chips coming off. Are you getting dust rather than chips? Then increase your feed rate or decrease your RPMs. If the bit is chattering, your feed rate is either too fast or you have too deep a depth of cut (DOC) for your machine. Chattering is when the cut doesn't have a smooth, uniform sound. The cut will often be rough rather than smooth.

Small diameter bits

One place where feed rate can be a big issue is when using a small diameter bit. A 1/16" diameter bit, for example, is fairly fragile and needs care in selecting a slower feed rate as well as a shallower depth of cut. It is a good idea to start slow and ramp up to a feed rate you feel comfortable with. Keeping the chip load in the recommended range will improve your chances of success. V Carving

When you are carving on a CNC router, it is often the case that the bit is moving in X, Y and Z. A lot of CAD/CAM software supports the concept of a Plunge Rate that is different from the specified feed rate. The plunge rate is the speed of movement when Z is changing. This is because the tool must follow the exact path and thus X and Y movement must be at the same feed rate as Z. This is useful for a number of bits, especially end mills that can not plunge and must be ramped down. However, for V Bits, a lower Plunge Rate can be a problem. Since carving often involves Z movement, you will mostly carve at the Plunge Rate. if you have a Feed Rate of 100 IPM and Plunge Rate of 50 IPM then, when your GCode is changing Z, you will be feeding at 50 IPM, the chip load will be 1/2 and possibly too small. Thus, you should look at the chip load for the Plunge Rate and consider increasing it to bring the chip load up to the manufacturer's recommendation. There is an added benefit here - your carve time will decrease significantly.

About Me

I'm a long time CNC enthusiast. I run a small company, Brookwood Design, that makes several breakout boards for grblHAL and love to help people get the most out of their CNC machines.

Recent Posts

See AllMultiple times a day, people ask for help with their CNC machine. Many supply enough detail for the experts in the group to give good...

I have been using the Internet from the very beginning and various forums for almost as long. And, I have been using special interest...

ความคิดเห็น